When you pick aluminum coil stock for your project in 2026, make sure the coil matches what you need. This helps you get good quality and save money. You should look at the material grade, thickness, finish, and if the supplier is reliable. Many people use aluminum because it is strong, does not rust easily, and is a good deal. Here are some key facts to remember:

- Aluminum is about 25% of all construction use in the world, and the Asia-Pacific area uses the most.

- More aluminum is being used in buildings, especially for big buildings and clean energy projects.

- People often make mistakes by not checking the material grade, thickness tolerance, surface finish, or if the supplier has the right certifications.

Pick trusted brands like Yutwin Aluminum Foil so you do not make these mistakes and you meet the standards for your next coil order.

Principales conclusiones

- Pick aluminum coil stock that fits your project. This helps you get good quality and saves money.

- Think about sustainability and material grade when you choose aluminum coils. This helps you follow new building rules.

- Always look at the thickness and tolerance of the coil. This stops expensive errors and makes your project last longer.

- Choose the best surface finish to make the coil look better. This also keeps it safe from weather damage.

- Work with trusted suppliers like Yutwin Aluminum Foil. They give good advice and help you avoid mistakes when ordering.

Choosing Aluminum Coil Stock: Key Factors

When you pick aluminum coil stock, you should think about a few main things. Your project goals, how much money you have, and where you will use the coil are all important. If you choose coil features that fit your project, you get better results. This also helps you avoid expensive mistakes.

Project Needs and End Use

Start by thinking about what your project needs. In 2026, three things are most important. These are sustainability, tight tolerance, and advanced manufacturing. Many companies want materials that are good for the planet and save energy. If you use aluminum coil stock made from recycled materials, you can cut down carbon emissions and energy use by up to 95% compared to new aluminum. This helps you follow green building rules and supports a circular economy.

You also need to choose the right alloy for your project. The end use tells you which alloy is best. Here is a table to help you match the alloy to your needs:

| Serie Alloy | Propiedades | Aplicaciones comunes |

|---|---|---|

| Serie 1000 | High corrosion resistance, excellent workability | Food and beverage packaging |

| Serie 3000 | Good formability, moderate strength | Beverage cans |

| 5000 Series | High strength, good weldability | Specialized applications requiring durability |

If you are working on a metal roofing project, you need a coil that does not rust and lasts a long time. For food packaging, you want a coil that is safe and easy to shape. Always check the details before you buy.

Budget and Cost

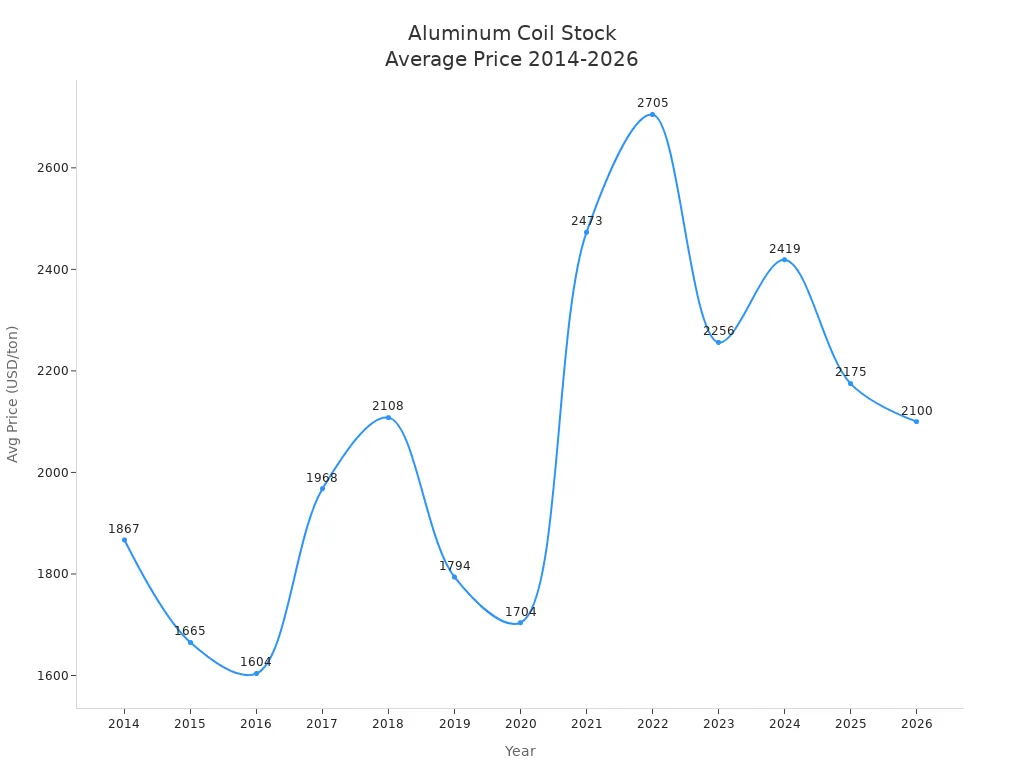

Your budget helps decide which coil you can get. Prices for aluminum coil stock change every year. In 2026, the average price is $2,100 for each metric ton. This is less than in 2024 and 2025. You can see the price trend in the chart below:

Price changes can make it hard to plan your spending. Here are some tips to help you with your budget:

- Buy early if you think prices will go up.

- Plan your stock so you do not run out.

- Buy in parts to spread out the cost and keep your supply safe.

If you work with a trusted supplier like Yutwin Aluminum Foil, you can get advice on when to buy and how much to order.

Climate and Style Fit

Where you use the coil and how you want it to look also matter. You need to think about the weather, the shape of your building, and how long you want the finish to last. The table below shows what you should think about:

| Factor | Descripción |

|---|---|

| Exposición ambiental | The location’s conditions, such as urban, coastal, or industrial areas. |

| Geometry | The complexity of surfaces, whether flat, curved, or intricate. |

| Aesthetic goals | The desired visual outcome, including color uniformity or variation. |

| Lifecycle expectation | The anticipated durability of the finish over time. |

| Budget priorities | The focus on initial costs versus long-term performance. |

If you build near the ocean, you need a coil that can handle salt and water. If you want a modern look, you can pick a special finish or color. Always match the coil to your style and the local weather.

Tip: Look at all these things before you buy. This helps you avoid problems and get the best value for your project.

Material Grade and Alloy Selection

Alloy Types and Tempers

You have to choose the right alloy and temper for your aluminum coil stock. This choice changes how your project works and how long it lasts. Each alloy series is good at different things. Here is a table that helps you see the most common choices:

| Serie Alloy | Propiedades clave | Usos comunes |

|---|---|---|

| 1xxx Series | Excellent conductivity, soft and ductile, great corrosion resistance | Electrical conductors, food packaging, chemical tanks |

| 3xxx Series | Moderate strength, good corrosion resistance, excellent formability | Residential siding, cookware, beverage cans |

| 5xxx Series | High strength, excellent corrosion resistance, weldability | Boat hulls, fuel tanks, pressure vessels |

| 6xxx Series | Heat-treatable, good machinability, strong yet formable | Structural components, bicycle frames, automotive parts |

| 7xxx Series | Extremely high strength, lower corrosion resistance, reduced weldability | Aerospace components, military applications |

You also need to check the temper. Temper tells you how the coil was made. It changes how easy it is to bend, stamp, or weld the coil. For example, O temper means the coil is soft and shapes easily. H14 is strong and works well for bending and stamping. H18 is very strong but not good for welding. Here is a simple guide:

| Temple | Características | Application Considerations |

|---|---|---|

| O | Annealed, high ductility | Suitable for deep drawing |

| H12 | Moderate strength | General bending |

| H14 | Good strength | Bending and stamping |

| H18 | High strength | Not recommended for welding |

| H24 | Good strength and ductility | General applications |

Tip: If you are not sure which alloy and temper to pick for your metal roofing project, you can ask Yutwin Aluminum Foil for help.

Strength and Corrosion Resistance

You want your coil to be strong and last a long time. The right material grade helps your project stay safe and follow building rules. Some alloys, like the 5xxx series, are great for tough places because they do not rust easily and are strong. If you use your coil outside or near the sea, pick an alloy that fights rust.

Tests show that aluminum coil stock can handle different weather and salt spray. In real weather, you might see more rust after two years, but the right grade keeps damage small. In salt-spray tests, most rust happens at the edges after 60 days. You can trust good coil to keep your project safe.

Note: Always check the grade and temper before you buy. This step helps you stop problems and keeps your project safe.

Thickness and Tolerance

Selecting the Right Thickness

You need to choose the correct thickness for your aluminum coil stock. The thickness affects how strong and long-lasting your project will be. If you work on a metal roofing project, you want a coil that can handle heavy rain and wind. For siding, you need a coil that looks good and protects your building. The table below shows the recommended thickness ranges for roofing and siding applications:

| Solicitud | Gama de espesores (pulgadas) |

|---|---|

| Techumbre | .0175 – .032 |

| Siding | .027, .032 |

When you select coil dimensions, always check the thickness. Thicker coils give you more strength, but they may cost more. Thinner coils work well for simple designs and save money. You should match the coil dimensions to your project needs. Yutwin Aluminum Foil offers many options, so you can find the right thickness for your job.

Tip: Measure your coil dimensions carefully before you order. This helps you avoid mistakes and keeps your project on track.

Importance of Tolerance

Tolerance means how close the coil thickness is to what you ordered. Tight tolerance gives you better quality and makes your project last longer. If the coil thickness changes too much, you may see problems like leaks or weak spots. The table below shows how thickness and tolerance work together:

| Espesor (mm) | Tolerance (mm) |

|---|---|

| 0.12 | ±0.01 |

| 0.25 | ±0.02 |

You should always ask your supplier about tolerance. Good suppliers, like Yutwin Aluminum Foil, keep tight control over coil dimensions. This helps you get a coil that fits your equipment and meets your standards. When you choose aluminum coil stock with the right thickness and tolerance, you protect your project and make it last longer.

Surface Finish and Appearance

Finish Options

You have many choices when it comes to the surface finish of your coil. The right finish can make your aluminum coil stock look great and last longer. Here are some popular finish options you can pick for your project:

- Painted finishes give you over 100 color choices. You can match almost any design.

- Water-based coatings protect your coil from fading, scratches, and scrapes.

- Textured finishes add a special look and feel to your building.

The table below shows why these finishes matter:

| Característica | Descripción |

|---|---|

| Resistencia a la corrosión | Coatings protect against rust and UV rays. |

| Atractivo estético | Many colors and finishes for creative designs. |

| Durabilidad | Tough coatings resist damage and last for years. |

| Low Maintenance | Easy to clean and needs little care. |

| Garantía | Some finishes come with a lifetime warranty for peace of mind. |

If you want high-quality products, Yutwin Aluminum Foil offers finishes that meet strict standards. You can trust these finishes to keep your coil looking new.

Aesthetics and Environmental Resistance

The finish you choose does more than change how your coil looks. It also helps your coil stand up to weather and tough conditions. A good finish protects your coil from rain, sun, and salt. This means your aluminum coil stock will last longer and need less work to keep it looking good.

A well-finished coil resists rust and fading. You do not have to clean it often. You save time and money because you do not need to fix or replace it as much. Many finishes also come with a guarantee, so you feel safe about your choice.

Tip: Pick a finish that matches your style and the climate where you will use the coil. This helps your project stay strong and look great for years.

If you want advice on the best finish for your project, you can ask Yutwin Aluminum Foil for help. Their team knows how to match finishes to different needs.

Coil Size and Equipment Compatibility

Choosing the right coil size helps your project run smoothly. You need to match the coil width and weight to your rollforming or cutting machines. If you pick the wrong size, you may face jams, waste, or even damage to your equipment. Yutwin Aluminum Foil offers many coil sizes, so you can find the best fit for your machines.

Width and Machine Limits

You should always check your machine’s width limits before you order. Most rollforming equipment works best with standard coil widths. The table below shows common widths and thicknesses for different metals, including aluminum:

| Metal Type | Common Widths (inches) | Common Thickness (Gauge) |

|---|---|---|

| Acero | 24, 36, 48, 60 | 10-gauge (0.1345) to 24-gauge (0.0239) |

| Aluminio | 24, 36, 48, 60 | 20-gauge (0.032) to 10-gauge (0.125) |

| Cobre | 12, 16, 24, 36 | 16-gauge (0.0508) to 24-gauge (0.0201) |

| Acero inoxidable | 24, 36, 48, 60 | 10-gauge (0.1345) to 26-gauge (0.0179) |

If your machine takes a 36-inch coil, you should not order a 48-inch coil. This mistake can slow down your work and cause safety risks. Always measure your equipment and check the specs before you buy.

Weight and Handling

Heavy coils need careful handling. You must think about safety when you move or install aluminum coil stock. The right safety gear protects you and your team from injuries. The table below lists important safety gear and why you need it:

| Safety Gear | Propósito |

|---|---|

| Hard Hat (ANSI Z89.1 Certified) | Protects your head from falling objects. |

| Steel-Toe Boots (ASTM F2413-18) | Shields your feet from heavy coils and slips. |

| High-Visibility Vest (ANSI Class) | Makes you easy to see in busy work areas. |

| Cut-Resistant Gloves (ANSI A5) | Keeps your hands safe from sharp coil edges. |

| Safety Glasses (ANSI Z87.1) | Guards your eyes from flying bits during cutting. |

| Hearing Protection (OSHA 85 dB+) | Lowers the risk of hearing loss from loud machines. |

| Back Support Belt | Supports your back when lifting or moving coils. |

You should always inspect your safety gear before use. Use cranes or forklifts for heavy coils. Secure each coil before you move it. Train your team on safe lifting and handling. Yutwin Aluminum Foil can help you choose the right coil size and give tips on safe handling.

Tip: The right coil size and safe handling keep your project on track and protect your team.

Ordering Aluminum Coil Stock and Accessories

Essential Accessories

When you buy aluminum coil stock, you need more than just the coil. Accessories help you finish your project and make it easier to install. Some common accessories are fasteners, sealants, protective films, and edge trims. You should see if your project needs special coatings or insulation. These extras can make your coil last longer and stay strong.

A good supplier like Yutwin Aluminum Foil has many accessories for you. You can ask them which items are best for your project. If you plan early, you will not have delays and you will have everything ready when your coil comes.

Tip: Always check your accessory list before you order. If you forget something, your work can slow down and cost more.

Accurate Ordering Tips

You need to plan carefully when you order coils and sheets. You want to get the right kind and the right amount for your project. Here are some good tips to help you:

- Work with mills to get your supply. This helps you avoid price jumps and keeps your supply steady.

- Pick green procurement. You can cut waste by choosing materials that are good for the planet.

- Talk with your supplier. If you share your inventory needs and green goals, you will not order too much or too little.

Deberías check your measurements for each coil two times. Make sure you know the smallest amount you can order. Some suppliers have limits, so you need to plan your order. Getting the right size and thickness helps you save money and keeps your project moving.

If you need help, Yutwin Aluminum Foil can help you order. Their team helps you match accessories and coil sizes to your machines. You get advice on how to order coils and sheets the right way.

Note: Ordering the right way saves you money and time. It also helps you finish your project without extra stress.

Supplier Reliability and Lead Times

Picking a supplier you can trust is very important. This helps your project go well and finish when you want. If you choose a bad supplier, you might have late orders, bad coils, or pay more money.

Evaluating Suppliers

You need to check each supplier before you buy from them. Here are some ways to help you pick the best one:

- Ask how they check for quality. Good suppliers will tell you how they look for problems in every coil.

- If you can, go see their factory. You can see if they follow safety and quality rules.

- Check if they have ISO certification. This means they follow world rules and keep good records for each order.

- Read what other customers say about them. Reviews show if people trust the supplier.

- Make sure they have all the right papers and training.

Yutwin Aluminum Foil is a supplier with good quality checks and a strong name. You can count on them to send what you need.

Tip: Always ask questions and look at papers before you pick a supplier. This helps you stop problems before they start.

Managing Delivery Schedules

You need to plan when your coils will come. This keeps your project moving and on time. Most suppliers can send regular coils in about two weeks. Some coils ship in one day if they are ready.

To stop delays, you should:

- Make a clear delivery plan that matches your project.

- Talk to your supplier often to check dates and changes.

- Use tools to watch your coil orders and get news.

- Change your plan if weather or other problems happen.

- Keep track of your coils so you do not buy too many or too few.

Talking with your supplier helps you get your coils when you need them. Yutwin Aluminum Foil can help you plan and keep your project going.

Note: Good planning and a trusted supplier help you finish your project on time and feel less stress.

Extra Tips for Success

Errores comunes que hay que evitar

You want your project to go well, so watch for mistakes. Many people forget to check their measurements twice before they order coil. This mistake can waste material or slow down your work. Some people do not read the technical data sheet. You should always look at the sheet to see if the aluminum coil stock fits your needs. Others do not think about the weather or place where they will use the coil. If you pick the wrong finish, your coil might not last long.

Here are some mistakes you should not make:

- Getting the wrong thickness or width for your machines.

- Not asking about tolerance or quality checks from your supplier.

- Forgetting to plan for things like fasteners or protective films.

- Not thinking about safety gear when you move heavy coils.

Yutwin Aluminum Foil helps you stop these mistakes by giving advice and clear product details. You can ask their team for help if you are not sure what to pick.

Tip: Make a checklist before you order. This helps you find mistakes early.

Staying Informed

You need to know what is new in the aluminum coil stock world. New rules and trends come out every year. If you stay up to date, you make better choices and follow the latest rules. The Aluminum Association gives technical standards and news for aluminum products. You can find facts, safety tips, and money studies in their resource library.

Here is a table with helpful resources:

| Resource | Descripción |

|---|---|

| Estándares de la industria | The Aluminum Association keeps technical standards for aluminum products. |

| Data & Resources | Find facts, safety tips, and news in the resource library. |

| Economic Impact | Learn how the U.S. aluminum industry helps factories and the economy. |

You can also read trade magazines or join online groups. Yutwin Aluminum Foil shares news and tips on their website. If you follow these sources, you will know about changes and keep your project going well.

Note: Staying informed helps you pick the best coil and avoid big mistakes.

You can make the best choice for your project by following these steps when you review aluminum coil stock options:

- Check the supplier’s history and reliability.

- Make sure the coil fits your machines.

- Compare grades and prices.

- Test how well the coil forms and works for your needs.

- Confirm the coil matches your end-use.

Review each factor before you buy. If you need help, talk with Yutwin Aluminum Foil or another expert. Careful planning leads to better results.

Preguntas más frecuentes

How do you choose the right aluminum coil for roofing?

You should check the material type and specs for your project. Look at the thickness, finish, and strength. Yutwin Aluminum Foil can help you match the coil to your roofing needs. Always review your order before you buy.

What should you ask metal roofing suppliers before you order?

Ask about coil quality, delivery time, and certifications. You should also check if they offer accessories for roofing. Make sure your order matches your machine size. Yutwin Aluminum Foil answers questions and helps you place the right order.

How many times should you check your order before buying roofing coil?

You should check your order at least two times. Review the size, thickness, and finish. This step helps you avoid mistakes. Yutwin Aluminum Foil suggests you double-check every order for roofing projects.

Why does order accuracy matter for roofing jobs?

Order accuracy keeps your roofing project on track. If you make a mistake, you may waste time and money. Always confirm your order with your supplier. Yutwin Aluminum Foil helps you get the right coil for roofing every time.

Can you change your order after you send it to the supplier?

You can sometimes change your order if the supplier has not started making your coil. Contact Yutwin Aluminum Foil quickly if you need to update your roofing order. Fast action helps you avoid delays.