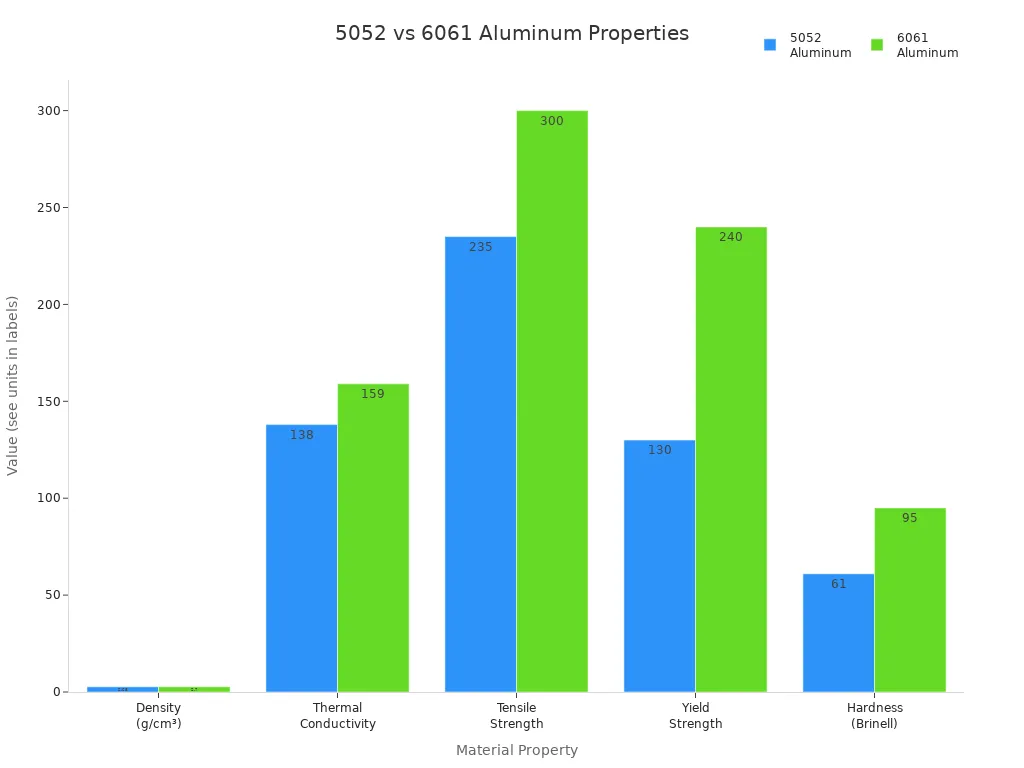

When selecting materials for construction, it’s essential to make informed decisions. The differences between 5052 vs 6061 aluminum alloy significantly influence your planning and execution. For instance, 6061 offers higher yield strength, while 5052 is more malleable and easier to weld. Additionally, the tempers such as 5052 H32 and 6061 T6 play a crucial role in determining the suitability of each alloy for specific applications. Refer to the chart below to compare the key features of these two alloys.

Key Takeaways

- 5052 aluminum bends and shapes easily. It is simple to weld. This makes it good for projects that need bending.

- 6061 aluminum is stronger. It is easier to machine. It works well for parts that hold heavy weight.

- Pick 5052 for boats and marine use. It does not rust in saltwater.

- Use 6061 for projects that need careful machining. It is good for strong frames and supports.

- Think about price. 5052 usually costs less. It is a smart pick if you want to save money.

Differences Between 5052 vs 6061

Quick Comparison Table

You can look at this table to see how 5052 and 6061 are alike and different. The table shows the most important things about both aluminum alloys.

| Property | 5052 Aluminum Alloy | 6061 Aluminum Alloy |

|---|---|---|

| Chemical Composition | Mg 2.2-2.8%, Cr 0.15-0.35% | Mg 0.8-1.2%, Si 0.4-0.8% |

| Strength | Higher because of magnesium | Excellent |

| Corrosion Resistance | Very good, especially in saltwater | Good, not as good in seawater |

| Density | 2.68 g/cm³ | 2.70 g/cm³ |

| Thermal Conductivity | 138 W/m-K | 151-167 W/m-K |

| Electrical Conductivity | Lower | Better |

| Tensile Strength | 210-260 MPa | 290-310 MPa |

| Yield Strength | ~130 MPa | ~240 MPa |

| Hardness (Brinell) | ~61 HB | ~95 HB |

| Machinability | Hard to machine, rough finish | Easy to machine, smooth finish |

| Formability | Very easy to shape and weld | Hard to shape, can crack |

| Cost | Cheaper | More expensive |

Main Distinctions Overview

When you look at 5052 and 6061, you see some big differences. These differences help you pick the best one for your job.

- 5052 has more magnesium and chromium. This makes it stronger and better at fighting rust, especially in water. People use it for boats and things that touch saltwater.

- 6061 has magnesium and silicon. This mix gives it great strength and makes it easy to cut and shape with machines. It is used for frames, parts, and things that need to be strong.

- 5052 is simple to bend and weld. You can shape it without breaking it. This is good for sheet metal and things that need to be joined together.

- 6061 is much better if you need to machine it. You get smooth, strong parts. But it is not easy to bend and can break if you try to bend it too much.

- 5052 costs less than 6061. If you want to save money and need something that does not rust, 5052 is a good pick. If you need something stronger and easier to machine, you might choose 6061, even though it costs more.

- Both alloys weigh about the same, but 6061 is stronger. It can take more force before it bends or breaks.

- 5052 is not heat-treated, so it stays flexible. 6061 is often heat-treated, which makes it stronger but not as bendy.

Tip: If you need something for boats or shaping, 5052 is usually better. If you need strong parts made by machines, 6061 is a good choice.

Knowing how 5052 and 6061 are different helps you pick the right one. Each alloy is good for different things, so your choice depends on what you need for your project.

Aluminum 5052 Properties

Chemical Composition

Aluminum 5052 is special because of what it is made of. It has a lot of aluminum. Magnesium and chromium are the main extra elements. The table below shows how much of each element is in it:

| Element | Composition Range |

|---|---|

| Aluminum (Al) | 95.7 – 97.7% |

| Magnesium (Mg) | 2.2 – 2.8% |

| Chromium (Cr) | 0.15 – 0.35% |

| Silicon (Si) | ≤ 0.25% |

| Iron (Fe) | ≤ 0.40% |

| Copper (Cu) | ≤ 0.10% |

| Manganese (Mn) | ≤ 0.10% |

| Zinc (Zn) | ≤ 0.10% |

Mechanical Strength & Fatigue

Aluminum 5052 is strong but also bends easily. You can check its strength in the table below:

| Property | 5052-H32 | 5052-O (Annealed) |

|---|---|---|

| Ultimate Tensile Strength (MPa) | 210 – 230 | 170 |

| Yield Strength (MPa) | 130 – 160 | 65 |

| Elongation (%) | 12 – 20 | 25 |

It can handle stress over and over without breaking. Fatigue strength is between 66 and 140 MPa. Some sources say it is 99 MPa for certain types.

Corrosion Resistance

Aluminum 5052 does not rust easily. Magnesium and chromium help protect it from rust. It works well in wet or salty places. This makes it better than many other aluminum alloys for stopping corrosion, like on boats.

Tip: Pick aluminum 5052 if your project will be outside or near the sea.

Weldability & Formability

You can weld and shape aluminum 5052 without trouble. It is good for welding because heat moves through it well. You can bend it into many shapes and it will not crack. Many companies use it for parts that must be strong after welding. It is easy to draw and harden, so you can make lots of products with it.

- You can weld 5052-O alloy with simple tools.

- You can make many shapes and keep them strong.

- You can finish it with shiny coatings for a nice look.

5052 H32 Temper

5052 h32 temper is very common. This means the alloy is made stronger and then softened a little. It gives you both strength and flexibility. Here are some important facts:

| Property | Value |

|---|---|

| Brinell Hardness | 60 |

| Elastic (Young’s) Modulus | 68 GPa |

| Elongation at Break | 12 % |

| Fatigue Strength | 120 MPa |

| Poisson’s Ratio | 0.33 |

| Shear Modulus | 26 GPa |

| Shear Strength | 140 MPa |

| Tensile Strength: Ultimate (UTS) | 230 MPa |

| Tensile Strength: Yield (Proof) | 180 MPa |

Typical Applications

Aluminum 5052 is used in many things because it is strong and does not rust. It is also easy to work with. Here are some ways people use it:

- Pressure vessels and hydraulic tubes

- Marine equipment, like fuel tanks

- Electronic boxes and frames

- Medical tools and hardware signs

- Cabinets and trailer air tanks

- Building fronts and kitchen appliances

- Aircraft, bus, and truck parts

- Road and name signs

Aluminum 5052 is a good choice for projects that need to last and stay strong in tough places.

Aluminum 6061 Properties

Chemical Composition

Aluminum 6061 is made from a mix of elements. Most of it is aluminum. It also has magnesium and silicon. These extra elements help give it special features. You can see the usual amounts in this table:

| Element | Percentage Range (% by weight) |

|---|---|

| Al | 95.85 – 98.56 |

| Mg | 0.80 – 1.20 |

| Si | 0.40 – 0.80 |

| Fe | 0.00 – 0.70 |

| Cu | 0.15 – 0.40 |

| Cr | 0.04 – 0.35 |

| Zn | 0.00 – 0.25 |

| Ti | 0.00 – 0.15 |

| Mn | 0.00 – 0.15 |

Mechanical Strength & Fatigue

Aluminum 6061 is strong and lasts a long time. You can check its strength in this table:

| Mechanical Property | Value (MPa) |

|---|---|

| Yield Strength | 145 |

| Tensile Strength | 241 |

| Fatigue Strength | 97.9 |

| Ultimate Tensile Strength | 310 |

It can handle stress many times before breaking. Its fatigue strength is between 112 and 131 MPa at 10 million cycles. This means it can take repeated use for years.

Corrosion Resistance

Aluminum 6061 does not rust easily. A thin layer forms on the surface to protect it. In places like the ocean, it resists rust best if it gets wet and dry often. But if there are pollutants, the layer can get damaged. This can cause rust, especially at the grain edges.

Note: If you use aluminum 6061 outside or near the sea, check for pitting or special rust.

Machinability & Weldability

Aluminum 6061 is easy to cut and shape with machines. It has a machinability rating of 90%. You can weld it using most methods. It works well if you use the right filler. This makes it a top pick for strong and exact parts.

6061 T6 Temper

6061 t6 is made by heating and aging the alloy. This makes it stronger and harder. Many companies use this type for tough and long-lasting parts.

Typical Applications

Aluminum 6061 is used in many areas because it is strong and light. It also does not rust much. Here are some ways it is used:

- Aerospace: wings, frames, and engine mounts

- Automotive: wheels, chassis, and suspension parts

- Marine: boat railings and non-submerged components

- Architecture: frames, beams, and curtain walls

- Industrial: machine frames and enclosures

You can also find it in bikes, motorcycles, and camera lenses. This shows how useful this alloy is.

Performance Comparison: 5052 vs 6061

Strength & Hardness

You need to know how strong and hard each alloy is before you choose. The table below shows the main differences between 5052-H32 and 6061-T6 aluminum alloys. You can see that 6061-T6 is stronger and harder than 5052-H32.

| Property | 5052-H32 | 6061-T6 | Remarks |

|---|---|---|---|

| Tensile Strength (MPa) | 210 – 260 | 290 – 340 | 6061-T6 offers higher strength |

| Yield Strength (MPa) | 130 – 195 | 240 – 280 | 6061 handles more load |

| Brinell Hardness (HB) | ~60 | ~95 | 6061 is much harder |

6061-T6 aluminum alloys give you better load-bearing capacity. You get more resistance to dents and scratches. If you need parts that must not bend or break easily, you should pick 6061-T6. 5052-H32 is softer and more flexible. You can bend it without cracking, but it will not hold as much weight.

Corrosion Resistance

You want your project to last, especially if it faces water or weather. 5052 aluminum alloys show strong performance in marine environments. You get a good balance of corrosion resistance and strength. 5052 works well against saltwater corrosion, so you can use it for boats or docks. 6061 aluminum alloys also resist rust, but they may get pitting corrosion in some conditions.

- 5052-H32 has better corrosion resistance than 6061-T6.

- Both aluminum alloys work well in saltwater, but 5052 is the safer choice for harsh environments.

If you need to protect your project from rust, 5052 is the better alloy. You can trust it for outdoor and marine uses.

Machinability & Formability

You may need to cut, shape, or weld your aluminum alloys. 6061-T6 is easy to machine. You get smooth finishes and precise parts. You can drill, tap, and mill it with less effort. 5052-H32 is harder to machine. You may see rough edges or need extra work to finish the part.

5052-H32 shines when you need to bend or form shapes. You can weld it easily. You can make curves and corners without cracks. 6061-T6 is not as flexible. If you try to bend it too much, it may break.

Tip: Choose 6061-T6 for parts that need exact shapes and smooth surfaces. Pick 5052-H32 for parts that need to be bent or welded.

Cost & Availability

You want to keep your project on budget. 5052 aluminum alloys usually cost less than 6061 aluminum alloys. You can find both alloys in many sizes and shapes. 6061-T6 may cost more because it is stronger and harder. If you need to save money and do not need high strength, 5052 is a smart choice.

- 5052 is more affordable for large projects.

- 6061 is worth the extra cost if you need strength and machinability.

You can buy both alloys from most suppliers. You should check prices and stock before you decide.

Choosing the Right Alloy

Key Selection Factors

You need to think about a few things before you pick 5052 h32 or 6061 t6. The table below shows what matters for your project:

| Factor | Description |

|---|---|

| Strength | Needed for parts that hold weight or force. |

| Machining | Good machinability gives smooth, accurate parts. |

| Weldability | Important if you need to join pieces. |

| Corrosion Resistance | Helps parts last longer, especially outside or near water. |

| Workability/Formability | Needed for bending or shaping without cracks. |

| Common Applications | Knowing where each alloy works best helps you choose. |

| Heat Treatment | Some projects need extra strength from heat treatment. |

When to Use Aluminum 5052

Pick 5052 h32 for some jobs. This alloy is best when you want:

- Strong corrosion resistance, especially in saltwater or marine places.

- Easy bending or shaping for tricky forms without cracks.

- Lower cost for big projects or when you want to save money.

5052 h32 is a good choice for marine gear, car parts, and outdoor signs. You get nice strength and long-lasting use.

When to Use Aluminum 6061

6061 t6 is better for jobs that need high strength and exact machining. Use this alloy when:

| Alloy Type | Key Characteristics | Typical Use Cases |

|---|---|---|

| 6061 | Higher strength, heat-treatable | Bridges, aircraft frames, machinery |

6061 t6 gives you tough, strong parts. You can use it for bridges, airplane frames, and heavy machines. This alloy is also good when you need heat treatment for extra strength.

Real-World Examples

You can see how these alloys are different in real life. The table below compares 6061 t6 and 5052 h32 in important properties:

| Property | Aluminum 6061-T6 | Aluminum 5052-H32 |

|---|---|---|

| Tensile Strength | Higher tensile strength | Moderate mechanical properties |

| Melting Temperature | Lower melting temperature | Higher melting temperature |

| Heat Treatability | Acceptable heat treatability | No heat treatability |

| Nugget Zone Width | Wider nugget zone | Narrower nugget zone |

| Softening Range | Wider softening range | Narrower softening range |

Tip: Pick 5052 h32 for boats or outdoor jobs. Choose 6061 t6 for strong, machined parts in bridges or planes.

Now you understand how 5052 and 6061 aluminum are different. 5052 does not rust easily and is simple to bend. This makes it great for boats and sheet metal jobs. 6061 is stronger and easier to cut with machines. It works well for building frames and airplane parts. You should always pick the alloy that fits your project best. If you want strong and exact parts, use 6061. If you need metal that bends and does not rust, use 5052. Remember to think about what your project needs before you choose.

FAQ

What is the main difference between 5052 and 6061 aluminum?

You will find that 5052 bends and welds easily. 6061 gives you higher strength and better machinability. Choose 5052 for forming and marine uses. Pick 6061 for strong, machined parts.

Can you weld both 5052 and 6061 aluminum?

You can weld both alloys. 5052 welds easily and keeps its strength. 6061 can lose strength in the weld area. Use the right filler and process for best results.

Which alloy resists corrosion better?

5052 resists corrosion better, especially in saltwater. You should use it for marine or outdoor projects. 6061 works well indoors or in less harsh environments.

Is 6061 aluminum more expensive than 5052?

Yes, 6061 usually costs more than 5052. You pay extra for higher strength and better machinability. For budget projects, 5052 is a smart choice.

What are common uses for 5052 and 6061 aluminum?

You see 5052 in boat parts, signs, and tanks. 6061 appears in bike frames, aircraft, and machine parts. Pick the alloy that matches your project needs.