When you look for aluminum sheet metal, you should make good choices. The vendor you pick can change your project’s price, quality, and time. Vendors with strong quality checks, like ISO 9001 certification, help stop problems and slowdowns. Early design checks and first article inspections also lower risk. If you pick the right material and vendor, you get better results and avoid expensive mistakes.

Tip: Always check a vendor’s past work and quality systems before you order.

Основные выводы

- Pick aluminum sheet metal vendors with good quality checks. Make sure they have certifications like ISO 9001 or AS9100. This helps you get material that is always reliable and consistent.

- Think about which aluminum grade fits your project best. Look at strength, formability, corrosion resistance, and welding needs. This helps you get the best results.

- Check prices from different vendors. Watch out for hidden fees. Think about the total cost over time. Remember to include shipping, storage, and long-term savings.

- Choose vendors with a strong history and on-time delivery. Read customer reviews to avoid delays and problems with quality.

- Find vendors who give good support and offer customization options. Quick after-sales service can help make your project easier and more successful.

Aluminum Sheet Metal Quality

When you pick aluminum sheet metal, you should check quality first. Quality changes how well your project works and how long it lasts. You need to look at grades, certifications, and if the metal is always the same.

Оценки

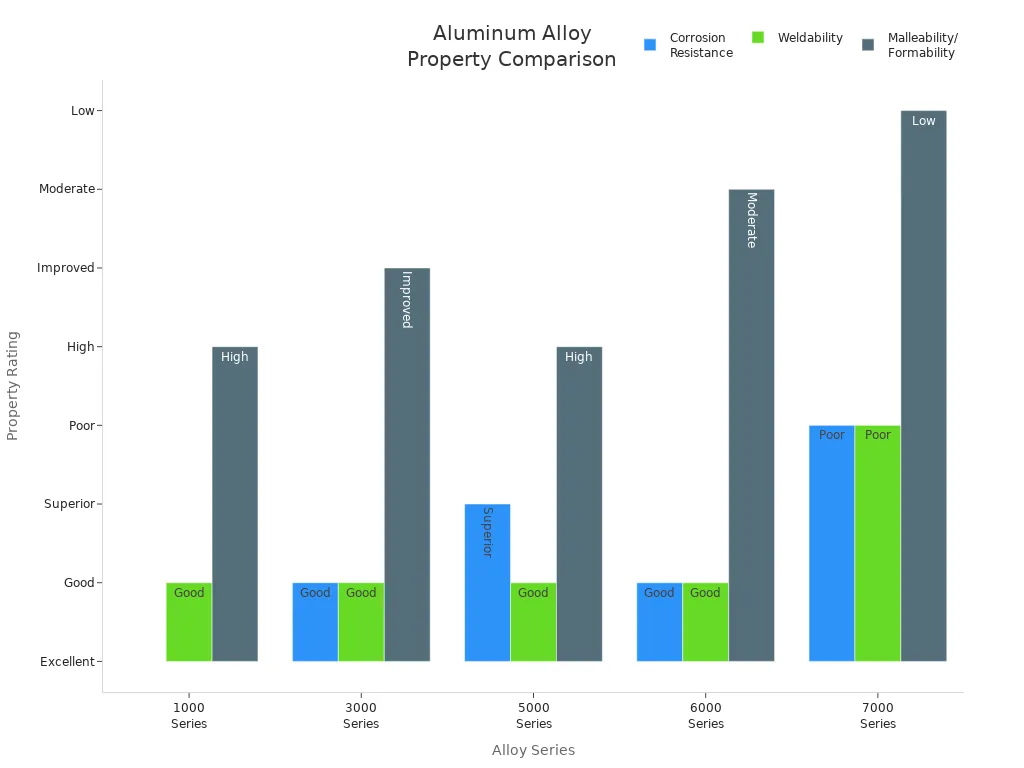

Aluminum sheet metal has many grades. Each grade is good for different things. You must choose the best grade for your project. Some grades bend easily. Others are strong or do not rust. The table below lists common grades and what they do best:

| Оценка | Прочность | Formability | Обработка | Свариваемость | Устойчивость к коррозии | Heat Treatability | Typical Uses |

|---|---|---|---|---|---|---|---|

| 5052 | Good (strongest non-heat-treatable alloy) | Excellent | Low (soft material) | Excellent | Excellent (resistant to saltwater) | Low (strengthened by cold working) | Marine applications, medical devices, kitchenware |

| 6061 | Excellent (stronger than 5052) | Excellent | Good (harder than 5052) | Excellent | Good | Excellent | Structural parts, bikes, electrical equipment, beverage cans |

| 7075 | Excellent (1.5x stronger than 6061) | Low (hard to form) | Excellent | Low (prone to cracking) | Excellent (saltwater resistant) | Excellent | Aerospace, marine, military, automotive industries |

5052 bends easily and does not rust in saltwater. It is used for boats and kitchens. 6061 is strong and works for many things, like bikes and machines. 7075 is very strong but hard to bend and weld. It is used in airplanes and military gear.

Each grade has different properties. These include how easy it is to bend, weld, and how well it resists rust. For example, 5052 bends without breaking. 7075 needs special care when welding. Aluminum has a natural layer that stops rust. Some grades do better in tough places.

Certifications

Certifications show that aluminum sheet metal follows safety and quality rules. If you work in aerospace or construction, you need the right certifications. Here are some important ones:

- AS9100 certification is needed for aerospace jobs. It checks more steps than ISO 9001 and looks at every part of making and testing the metal.

- You need to be able to trace the metal. This means you get records for heat treatment, chemical makeup, and test results.

- Vendors must keep papers about storage, testing, and problems.

- Testing standards check chemical content, hardness, grain, and surface finish.

- Quality control means checking the metal often and writing down results.

- Good vendors teach their workers these rules and keep training records.

If you buy from a supplier with AS9100 or ISO 9001:2015, you know they follow high standards. This lowers your risk and helps you follow industry rules.

Примечание: Always ask for certification papers before you buy. This keeps your project safe and helps you avoid mistakes.

Consistency

You want every batch of aluminum sheet metal to be the same. Vendors use many steps to keep quality steady:

- Visual checks find scratches, dents, or color changes.

- Tools measure how rough the surface is.

- Gauges check that coatings like anodizing are even.

- Special tests, like dye penetrant, find hidden cracks.

- Mechanical tests check strength, hardness, and toughness.

- Vendors keep records for each batch, including test results and certificates.

Each batch gets a heat number. This is a code stamped on the metal. The number links to a report with the metal’s properties. You can trace every piece from the mill to your project. This system helps you get the same quality every time.

Tip: Ask your vendor how they track and test their aluminum sheet metal. Good records mean fewer problems.

Расходы

When you buy aluminum sheet metal, you need to think about more than just the sticker price. The way you buy, the amount you order, and where you get it from all change the final cost. Let’s look at what affects your total price.

Price Comparison

You have several ways to buy aluminum sheet metal. Each option changes how much you pay per unit and what you spend on shipping.

- Оптовая: Buying in bulk from mills or large suppliers gives you the lowest price per sheet. You often need to meet a minimum order, like 30 to 100 sheets or rolls. This works best for big projects or steady production.

- Local Vendors: Local shops let you buy small amounts. You can pick up your order, which saves on shipping. Many local vendors also cut metal to size, so you only pay for what you need.

- Online Vendors: Online stores offer a wide selection. They have strict shipping size and weight limits. If your order is too big, you pay extra for freight shipping. This can make online orders more expensive for large or heavy sheets.

- Remnants: Remnant metal comes from leftover pieces after big jobs. These pieces cost much less than new sheets from mills. Remnants are great for small projects or when you do not need a full sheet. You can often buy them without a minimum order.

Tip: For small jobs, check local shops or remnant suppliers. You can save money and avoid high shipping costs.

Hidden Fees

The price you see is not always the price you pay. Watch out for hidden fees that can raise your total cost.

- Weight Calculation Differences: Vendors may use different ways to figure out the weight of your order. Some use actual weight, while others use a standard or “theoretical” weight. This can change the final price, especially if the thickness or weight is not exact.

- Overseas Sourcing Risks and Charges: If you buy from overseas, you may face extra costs. These include shipment delays, fuel surcharges, and fees if your goods get stuck at a port. Political events can also force changes in shipping routes, adding more charges.

- Tariffs and Tax Changes: New tariffs or taxes can appear without warning, especially during elections or trade disputes. These costs may not show up in your first quote but will add to your bill.

- Shipping Terms and Transfer of Title: The rules for shipping decide who pays for transport and when you own the goods. If you do not understand these terms, you might pay for damage or extra shipping costs.

⚠️ Alert: Always ask your vendor to explain all fees before you buy. This helps you avoid surprises.

Value

You want the best value, not just the lowest price. Think about how much you need, how long the metal will last, and what you save over time.

Some suppliers do not require a minimum order. This helps if you only need a small amount, but you may pay more per sheet. Suppliers with minimum orders often give discounts for buying more, but you must spend more upfront and store extra metal.

| Product Type | Typical MOQ | Bulk Discount | Upfront Cost | Inventory Needed |

|---|---|---|---|---|

| Aluminum Sheet Rolls | 50 rolls | Yes | High | Yes |

| Perforated Aluminum Sheets | 30 sheets | Yes | Средний | Yes |

| 24 Gauge Aluminum Sheets | 100 sheets | Yes | High | Yes |

| Remnants | None | No | Low | No |

When you compare aluminum sheet metal to other metals, you see more than just the price per pound. Aluminum costs more to buy and shape than steel, but it resists rust better and weighs less. This means you spend less on maintenance and transport. Over time, aluminum can save you money, especially if you use it for many years.

| Characteristic | Алюминий | Сталь |

|---|---|---|

| Raw Material Cost | Higher (50-75 cents/lb) | Lower (20-60 cents/lb) |

| Fabrication Cost | Higher (special welding/forming) | Lower (easier welding) |

| Устойчивость к коррозии | High (needs little care) | Needs coatings and care |

| Weight | Light (2.7 g/cm³) | Heavy (7.75-8.05 g/cm³) |

| Scrap Value | High ($0.94/kg) | Low ($0.10/kg) |

| Lifecycle Cost Break-even | 21 years (maritime), 33 years (urban) | Cheaper at first |

| Operational Savings | Fuel and handling savings | None |

Copper lasts even longer and has a higher scrap value, but it costs much more at the start. For most jobs, aluminum gives you a good balance of price, weight, and long-term savings.

Примечание: Always look at the total cost over the life of your project, not just the price today.

Надежность

When you pick a vendor, you want to trust them. You need them to deliver what you ask for on time. Reliability means your supplier helps your project stay on schedule. You should check their past work, how they ship, and what other buyers say.

Track Record

A vendor’s track record shows how well they help others. You can look at a few things to decide:

- How long they have worked in the field

- If they use tools like CNC machines and laser cutters

- If they have certifications for industry standards

- If they can fill big orders and meet deadlines

- If they have plans for supply chain issues

- If their customer service is quick and helpful

- If they offer extra services to make things easier

These points show if a vendor can meet your needs and fix problems fast.

Delivery

Getting your order on time keeps your project moving. You should ask vendors about their delivery rates and how they handle orders. The table below lists important things to watch:

| Метрика | Описание | Why It Matters |

|---|---|---|

| On-time Delivery | Vendor brings products when promised. | Stops delays and keeps your schedule safe. |

| Defect and Return Rates | Shows how often products have issues or get sent back. | Tells if the vendor meets your quality needs. High rates mean more trouble for your project. |

| Non-Conformance | Counts times products do not match your specs or sizes. | Helps you avoid rework and keeps your project running smoothly. |

You should ask for these numbers before you buy. Vendors with good delivery records help you avoid costly delays.

Reviews

Customer reviews give you honest feedback. Many buyers say vendors have good quality and fast service. Reviews talk about friendly support and easy ordering. Customers also like fair prices and reliable shipping. Most reviews come from small businesses and experts. When you see lots of good reviews, you know the vendor works hard to keep customers happy.

Tip: Read customer testimonials before you pick a vendor. Good reviews mean you can trust them with your project.

Услуга

Support

You need good support to finish your project well. Good vendors help you pick the right materials. They stop you from making expensive mistakes. They answer your questions fast and help you at every step. You can get:

- Tips on how to handle and store metal safely.

- Help choosing the best alloy and size for your needs.

- Ideas for cutting, bending, or coating to save money.

- Clear order info and quick replies to your questions.

- Delivery that saves you time and work.

- Fast help if there is a problem with your order.

Many vendors also help with design. They can give you drawings and help plan your parts. This makes your job easier and helps you do better work.

Настройка

Sometimes you need special sizes, finishes, or shapes. Vendors let you change your order in many ways. The table below shows some common choices:

| Customization Aspect | Подробности |

|---|---|

| Alloy Range | Choices like 3003, 5052, 6061, 7075 for different uses |

| Finishing Options | Anodizing (with color), powder coating, brushed, chemical coatings, custom paint/marking |

| Tolerances | Стандарт ±0.005” to 0.010”, tighter on request |

| Max Part Size | Up to 120″ x 60″ |

| Fabrication Methods | CNC machining, laser cutting, forming, die casting |

You can also ask for engraving, bending, or special packing. Some vendors have online tools for quick quotes and easy orders. This helps you get what you want.

After-Sales

Good service does not end after you get your order. Vendors help you fix problems fast. You can expect:

- Quick help with damaged goods or quality issues.

- Tips for shipping and special packing.

- Updates and support with photos, videos, or live chat.

- Flexible delivery and good service for your next order.

Ongoing help builds trust and keeps your project on track. You know your vendor will help you at every step.

Risks

When you choose a vendor, you face several risks that can affect your project. You need to know about these risks before you make a decision.

Delays

Project delays can happen for many reasons. Your vendor might not have enough stock. Shipping problems can slow down delivery. Sometimes, vendors promise fast service but do not meet deadlines. If you buy from overseas, customs checks or port issues can add days or weeks. Delays can stop your work and cost you money. You should always ask vendors about their average delivery times and how they handle late shipments.

Tip: Ask for a clear delivery schedule before you order. Reliable vendors share tracking updates and let you know about any problems right away.

Quality Issues

Quality problems can ruin your project. You might get sheets with dents, scratches, or wrong sizes. Some vendors do not check their products well. If you buy secondary or remnant metal, you may see more cosmetic flaws or uneven thickness. These issues can make your parts weak or hard to use. You may need to spend extra time fixing or replacing bad material.

- Check if your vendor offers quality guarantees.

- Ask for photos or samples before you buy.

- Review their return and replacement policies.

Overruns

Cost overruns can surprise you. Hidden fees, extra shipping charges, or last-minute price changes can push your budget higher. If you order more than you need, you pay for storage and waste. Remnant metal can save money, but limited supply may force you to buy new sheets at a higher price later.

| Risk Type | Example Problem | How to Reduce Risk |

|---|---|---|

| Delays | Late shipments | Confirm lead times, track orders |

| Quality Issues | Dents, wrong thickness | Ask for samples, check reviews |

| Overruns | Extra fees, buying too much | Get full quotes, plan purchases |

⚠️ Alert: Always read the fine print in your contract. This helps you avoid surprise costs and keeps your project on track.

You should think about quality, price, trust, and help when picking aluminum sheet metal.

- Look at how strong the metal is, what it looks like, and how it is made. Pick what fits your project best.

- Ask for samples, check for certifications, and make sure you know what you are getting. This helps you avoid problems.

- Choose vendors who have done good work before and give helpful support.

- Try to buy more at once if you can. This can save money and make sure your metal is always the same.

If you do these things, you will make better choices and get good results.

Часто задаваемые вопросы

What is the best way to check aluminum sheet metal quality?

You should ask for samples and review certifications. Look for ISO 9001 or AS9100. Check for surface defects and ask about testing methods. Good vendors share test results and quality records.

How do you avoid hidden fees when buying aluminum sheet metal?

You need to request a full quote before you order. Ask about shipping, taxes, and extra charges. Review the contract for details. Use a checklist to compare costs.

Tip: Always ask vendors to explain every fee.

Can you buy small amounts of aluminum sheet metal?

Yes, you can buy small quantities from local shops or remnant suppliers. Online vendors also offer small orders. You may pay more per sheet, but you avoid storage costs.

| Source | Minimum Order | Price per Sheet | Storage Needed |

|---|---|---|---|

| Local Shop | None | Higher | No |

| Remnant Seller | None | Lowest | No |

| Online Vendor | 1-5 sheets | Средний | No |

What should you do if your order arrives damaged?

You should contact the vendor right away. Take photos of the damage. Ask about their return or replacement policy. Good vendors help you solve problems quickly.

⚠️ Alert: Always check your order as soon as it arrives.