You can see aluminum coils used in many places. Each grade has special features. The biggest differences are in what they are made of and how strong they are. The 1000 series is made with pure aluminum. Other series are stronger and used for special jobs. These differences help people pick the best coil for building, planes, or packaging.

Aluminum coil grades affect how well they work for each task.

Type/Application Forecasted Production (2023-2028) Forecasted Revenue (2023-2028) Forecasted Price (2023-2028) Aluminum Coil Type 1 N/A N/A N/A Aluminum Coil Type 2 N/A N/A N/A Aluminum Coil Application 1 N/A N/A N/A Aluminum Coil Application 2 N/A N/A N/A Yutwin Aluminum Foil can help you pick the right coil.

Principaux enseignements

- Aluminum coils come in many grades and types. Each type is made for a special use. Pick the right coil for your project’s needs.

- Wrought alloys are strong and bend easily. They work well for building things. Cast alloys cost less and fit complex shapes. They are good for car parts.

- Think about the finish of aluminum coils. Mill finish is simple to paint. Painted coils give color and shield the metal. Anodized coils stop rust the best.

- Strength and rust resistance matter when picking coils. Bigger series numbers mean the coil is stronger.

- Talk to suppliers like Yutwin Aluminum Foil. They can help you choose the best coil. Make sure it fits what your project needs.

Types and Grades of Aluminum Coil

Wrought vs. Cast Aluminum Alloys

There are two main types of aluminum coils. These are wrought alloys and cast alloys. Wrought aluminum alloys are strong and bend easily. People use them for building things, ships, and planes. Cast aluminum alloys are good for making tricky shapes. They cost less and work well for car and machine parts.

| Property/Application | Wrought Aluminum Alloys | Cast Aluminum Alloys |

|---|---|---|

| La force | Stronger and more ductile | Cost-efficient for complex shapes |

| Applications typiques | Structural, high-performance uses | Automotive, consumer, machinery industries |

Alloy Series Overview (1000, 3000, 5000, 6000, 7000)

You can pick from many alloy series for aluminum coils. Each series has a main element and special use. The table below shows how they are different:

| Series | Main Alloying Element | Key Characteristics | Applications typiques |

|---|---|---|---|

| 1000 | None (99.5%+ Aluminum) | Excellent workability, corrosion resistance, high conductivity | Cookware, curtain wall plates |

| 2000 | Copper | High strength, used in aviation | Aircraft structural components |

| 3000 | Manganèse | Good formability, corrosion resistance | Beverage cans, chemical apparatus |

| 5000 | Magnésium | Haute résistance, bonne résistance à la corrosion | Marine applications, heat sinks |

| 6000 | Silicon and Magnesium | Good corrosion resistance, workability | Aircraft joints, low-pressure armaments |

| 7000 | Zinc | Maximum strength, used in high-demand industries | Aircraft parts, bicycle components |

The 1000 series is pure and easy to shape. The 3000 and 5000 series are stronger and fight rust better. The 6000 and 7000 series are best for hard jobs like making plane parts.

Key Grades: 3003, 5052, 6061, 2017, 2014

Sometimes you need a certain grade for your project. Here are some common grades and what they are used for:

| Aluminum Grade | Utilisations courantes |

|---|---|

| 3003 | Cookware and food service equipment, HVAC components, chemical equipment, general sheet metal fabrication |

| 5052 | Marine environments, fuel tanks, pressure vessels, structural and load-bearing components |

| 6061 | Aircraft fittings, marine frames, electronic parts, pipelines |

| 2017 | Rivets, structural parts, aerospace components |

| 2014 | Heavy-duty forgings, aircraft parts, truck frames |

Each grade is made for a special job. For example, 3003 is good for cookware and HVAC. 5052 is strong and does not rust, so it works in boats. 6061 is used for planes and pipes. Grades 2017 and 2014 are tough and used in planes and trucks.

Tip: When you pick a type or grade of aluminum coil, think about how strong it is, how easy it is to work with, and where you will use it. Yutwin Aluminum Foil can help you find the right coil for your needs.

Now you know the main things about aluminum coil. You can see how each type is used for different jobs. This helps you choose the best coil for your project.

Types of Aluminum Coils by Finish

When you pick aluminum coils, you should think about the finish. The finish changes how the coil looks and works in different places. There are three main finishes: mill finish, painted, and anodized. Each finish gives the coil special features and helps it last longer.

Mill Finish Aluminum Coils

Mill finish aluminum coil comes right from the factory. It has a shiny metallic look and a flat or dull feel. This finish does not have any extra layers. It is good if you want to paint or coat it later. Mill finish coils stick well to paint and glue. People use them in building for trim, window frames, gutters, and drains. Electrical parts use mill finish coils because they let electricity flow well. Many things people use, like aluminum foil and cans, have this finish. Yutwin Aluminum Foil sells mill finish coils for these uses.

Tip: Mill finish aluminum coils are great if you want to add your own paint or coating.

| Type of Finish | Surface Properties | Durabilité |

|---|---|---|

| Mill Finish | Shiny metallic look, flat or dull feel | Paint sticks well, but no extra protection |

Painted Aluminum Coils

Painted aluminum coil has a layer of paint on it. This paint protects the metal and adds color. You can choose from many colors and textures. Painted coils do not scratch or chip easily, so they last longer outside. These coils are good for building panels, signs, and roofs. You see painted coils where looks are important and you want more protection.

| Type of Finish | Surface Properties | Durabilité |

|---|---|---|

| Painted | Many colors and textures, does not scratch or chip easily | Lasts longer than regular paint, good for outside use |

Note: Painted aluminum coils help your project look nice and stand up to weather.

Anodized Aluminum Coils

Anodized aluminum coil gets a thick layer that protects the metal. This finish makes the coil strong against rust and damage. You use anodized coils in tough places, like outdoor signs or building walls. The surface is smooth and shiny. Anodized coils last a long time and keep their color. Yutwin Aluminum Foil can give you anodized coils for hard jobs.

| Type of Finish | Surface Properties | Durabilité |

|---|---|---|

| Anodized | Thick protective layer, fights rust | Very strong, good for tough places, does not wear out easily |

Callout: Anodized aluminum coils give the best protection for outside and factory projects.

When you look at the finishes, you see that mill finish coils are easy to change, painted coils look nice and protect well, and anodized coils are the strongest. Each finish changes how the aluminum coil works, so you should pick the right one for your job.

Aluminum Coil Properties Comparison

When you look at aluminum coils, you should check their main features. These are things like how strong they are, how much they bend, if they rust, and how easy they are to shape. You also need to think about how easy they are to weld and what the surface looks like. Each feature changes how you use the coil in your project. Different grades and finishes make the coil act in different ways. This helps you pick the best coil for your job.

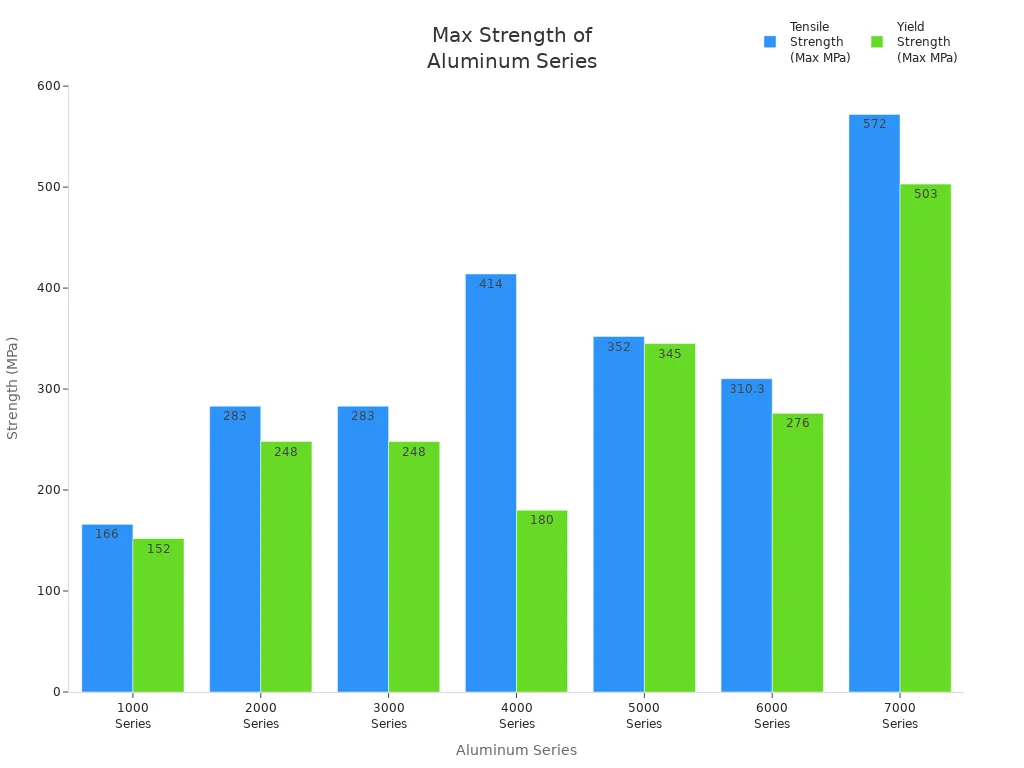

Mechanical Strength and Ductility

It is important to know how strong and bendy your coil is. Mechanical strength means how much force the coil can take before it breaks. Ductility tells you how much you can bend or stretch the coil before it snaps. These two things matter a lot for building, cars, and packaging.

Here is a table that shows the range of mechanical properties for aluminum coils:

| Propriété | Range | Description |

|---|---|---|

| Tensile Strength | 60 – 250 MPa | How much pulling force the coil can take. |

| Yield Strength | 30 – 200 MPa | When the coil starts to bend for good. |

| Elongation (%) | 5 – 30% | How much you can stretch the coil. |

Different alloy series have different strengths. The 1000 series is soft and easy to shape. The 7000 series is very strong and used for hard jobs. Here is a table that compares the main series:

| Series | Composition | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|---|

| 1000 Series | 99.00%-99.99% Aluminum | 82-166 | 28-152 |

| 2000 Series | 2.2%-6.8% Copper | 110-283 | 41-248 |

| 3000 Series | 0.3%-1.5% Manganese | 110-283 | 41-248 |

| 4000 Series | 3.6%-13.5% Silicon | 172-414 | 45-180 |

| 5000 Series | 0.05%-5.5% Magnesium | 124-352 | 41-345 |

| 6000 Series | 0.2%-18% Silicon | 124-310.3 | 55.2-276 |

| 7000 Series | 0.8%-8.2% Zinc | 228-572 | 103-503 |

If you need a coil that is very strong, pick a higher series. If you want to bend or shape the coil, choose one with higher elongation. Yutwin Aluminum Foil can help you find the right coil for your needs.

Résistance à la corrosion

Corrosion resistance means how well the coil stands up to water, air, and chemicals. This is important if you use the coil outside or in wet places. The finish you pick changes how well the coil fights rust.

- Anodized aluminum coils are best at stopping rust. The anodizing process gives the coil a thick layer that protects it. This layer helps the coil last longer. You can also get different colors with anodized coils.

- Painted aluminum coils have a paint layer that protects the metal. How well it works depends on the paint type. Painted coils are good for outside, but do not last as long as anodized coils.

- Mill finish aluminum has no extra layer. It does not fight rust as well. You should use it inside or add your own coating.

Note: Anodized coils also do not scratch or wear out easily. But strong acids can hurt the protective layer over time.

If you want the best protection, pick anodized or painted coils. Mill finish coils need more care in tough places.

Fabrication and Workability

You need to know how easy it is to cut, bend, or shape your coil. Workability and fabrication depend on the alloy and the finish. Some grades are easy to form, while others are harder but stronger.

Here is a table that shows the main factors that affect workability:

| Facteur | Description |

|---|---|

| La force | How much force the coil can take before breaking. |

| Machining | How easy it is to cut or drill the coil. |

| Soudabilité | How well the coil joins with other pieces when you weld. |

| Résistance à la corrosion | How well the coil stands up to rust and chemicals. |

| Workability/Formability | How easy it is to bend or shape the coil. |

| Heat Treatment | How heating or cooling changes the coil’s strength and flexibility. |

If you want to make tricky shapes, use 1000 or 3000 series coils. These grades are easy to bend and form. If you need more strength, use 5000 or 6000 series. These grades are good for strong parts and cast-rolled substrates. Yutwin Aluminum Foil has coils for both easy and hard jobs.

Weldability and Surface Finish

Weldability means how well you can join coils together. Surface finish is how the coil looks and how well it resists damage. Some grades are easier to weld than others. Some finishes give a smoother look.

Here is a table that compares weldability and surface finish for common alloy types:

| Alloy Type | Soudabilité | Surface Finish Characteristics |

|---|---|---|

| 5754 | Superb welding with many methods | High corrosion resistance, moderate strength, good formability |

| 6061 | TIG or MIG welding works well | Excellent strength-to-weight ratio, moderate ductility |

| 6063 | Excels in welding all thicknesses | Smooth surface, good corrosion resistance |

| 1100 | Very easy to weld | Excellent corrosion resistance, low strength |

| 1350 | Easy to weld in most ways | Strong, great corrosion resistance, reliable in special uses |

If you want a smooth and shiny coil, pick anodized or painted finishes. Mill finish gives a plain metallic look. For strong welded joints, pick grades like 5754, 6061, or 1100. These are also good for cast-rolled substrates and electrical parts.

Tip: Always pick the weldability and surface finish that fit your project. This helps your coil last longer and work better.

Yutwin Aluminum Foil can help you choose the best coil, whether you need strength, easy shaping, or a special finish.

Applications of Aluminum Coils

Aluminum coils are important in many industries. You can find them in buildings, cars, air systems, packaging, and airplanes. Each industry uses a special type or grade of aluminum coil. This is because every job needs different features. Picking the right coil gives you better products that last longer.

Construction and Architecture

Aluminum coils are used in many building parts. They are light and do not rust. This makes them good for inside and outside. Here are some ways people use them:

- Roofing systems use aluminum coils to keep water out. These roofs last long and do not rust.

- Gutters and drains made from aluminum coil last longer and leak less.

- Curtain walls and outside panels use aluminum coils for strength and looks.

- Siding and panels use aluminum coil to look like wood or stone but last longer.

- HVAC ductwork uses aluminum coils because they move heat well and do not rust.

- Ceiling systems use aluminum panels with holes for sound and design.

You can choose painted or anodized finishes to match your building style. Yutwin Aluminum Foil has many choices for building projects. You can find the right coil for your needs.

Automotive and Transportation

Aluminum coils make cars, trucks, and trains lighter and stronger. Different parts need different grades. For example, 3003 aluminum coil bends easily. It is used for truck and trailer insides. 5052 aluminum coil is stronger and does not get tired. It is used for fuel tanks and strong parts.

| Aluminum Type | Propriétés | Applications |

|---|---|---|

| 3003 | Bends easily, medium strength | Truck and trailer insides |

| 5052 | Stronger, fights fatigue, resists rust | Fuel tanks, strong parts, boats |

The bottom line: 3003 Aluminum is great for general jobs because it bends well and costs less. 5052 Aluminum is best for strong jobs because it is tough and does not rust, even in water.

Good aluminum coils make vehicles safer and work better. Yutwin Aluminum Foil gives coils for the car industry.

HVAC and Electrical

Aluminum coils are used in heating, air, and cooling systems. They help move heat and keep air clean. In electrical work, aluminum coil is good because it carries electricity and does not rust.

When you pick an aluminum coil for HVAC or electrical work, check these things:

| Critères | Description |

|---|---|

| Technical Specifications | Look at tube size, wall thickness, and fin density. |

| Industry Compliance | Make sure the coil follows safety and environment rules. |

| Performance Metrics | Check heat transfer, pressure drops, and rust resistance. |

| Cost-Efficiency | Think about cost and energy savings. |

| Assurance qualité | Ask for certificates and check how it is made. |

| Integration Capabilities | Make sure the coil fits your system and works with your refrigerant. |

| After-Sales Support | Pick a supplier who helps you after you buy and gives spare parts. |

Yutwin Aluminum Foil sells coils that meet high standards for HVAC and electrical jobs.

Packaging and Consumer Goods

Aluminum coils are great for packaging. You see them in cans, food wrappers, and medicine packs. Aluminum coil is light, so it is easy to move and store. It is strong and keeps things safe when shipping. It does not rust, so it protects food and drinks from air and water.

- Aluminum coil keeps drinks fresh in cans and stops taste changes.

- In food packaging, it blocks water and light, so food stays safe and fresh.

- In medicine packs, it keeps pills away from air and keeps them working.

You can trust aluminum coils to keep your things safe and fresh. Yutwin Aluminum Foil is a trusted supplier for packaging and consumer goods.

Aerospace and Specialized Uses

Aluminum coils are used in airplanes and special machines. These jobs need coils that are strong and light. Different alloys give the right mix of strength, weight, and rust resistance.

| Alliage | Key Characteristics | Applications in Aerospace |

|---|---|---|

| AA 7068 | Very strong, light weight | Military parts |

| AA 7050 | Great rust resistance and lasts long | Aircraft structure |

| AA 7075 | High strength, easy to shape | Aircraft parts |

| AA 5052 | Flexible, resists saltwater rust | Marine and aircraft parts |

| AA 2024 | Good strength-to-weight ratio | Wings and main body |

| AA 2014 | Strong and lasts long | Inside aircraft parts |

| AA 6061 | Used for many things | Wings and main body |

You need to pick the right aluminum coil for each airplane job. The right coil helps planes fly safely and last longer. Yutwin Aluminum Foil has coils for the tough needs of the aerospace industry.

Tip: Always match the grade and finish of your aluminum coil to the job. This helps you get the best results in any industry.

Choosing the Right Aluminum Coil

Specification Considerations

When you choose an aluminum coil, you need to look at important features. These features help you decide if the coil will work for your project. You should check:

- Soudabilité

- Wettability

- Tensile strength

- Corrosion resistance

- Formability

You also need to think about deep drawing, anodizing quality, minimum earring, and fine grain. These details matter for jobs that need special shapes or finishes. Always make sure your coil meets industry standards like ASTM, EN, or GB/T. This helps you get the right quality for your work.

Pricing and Cost Factors

The price of aluminum coils can change for many reasons. You will see differences based on grade, finish, and order size. Here is a table that shows what affects the cost:

| Facteur | Description |

|---|---|

| Alloy composition | Different grades like 1050, 3003, 5052, 6061 |

| Temper/hardness | Variants such as H14, H24, O, etc. |

| Surface finish | Options include mill finish, color-coated, etc. |

| Thickness and width | Variability in dimensions affects pricing |

| Order quantity | Larger orders may reduce per-unit costs |

| Packaging requirements | Specific needs can influence overall costs |

| Raw material index | Prices linked to LME Aluminum Price |

| Supply-demand trends | Global market conditions impact pricing |

If you want the best value, talk with suppliers like Yutwin Aluminum Foil. They can help you find the right coil for your budget and needs.

Matching Coil Type to Application

You need to match the aluminum coil to your project. Follow these steps:

- Define the end use. Know what you need the coil to do.

- Select the emboss pattern. Pick one that looks good and works well.

- Choose the alloy. Think about where you will use it and what strength you need.

- Determine the gauge. Decide how thick the coil should be.

- Consult with suppliers. Make sure the coil fits your needs.

The right choice depends on the job. For example, 3003 and 3105 alloys work well for roofing because they resist rust and bend easily. Alloy 5052 is better for boats because it is strong and fights saltwater. Yutwin Aluminum Foil can help you pick the best aluminum coil for any use.

Aluminum coils come in many types and grades. Each type has special features. These features depend on how it is made and what is inside.

- Wrought alloys are shaped by machines. Cast alloys are made in molds.

- The mix of metals, the finish, and things like strength and rust resistance decide where you use each coil.

- Always look at the details and price before you buy.

- Yutwin Aluminum Foil can help you pick the best coil for your project.

| Facteur | Description |

|---|---|

| Alloy Composition | Different grades give you special strength and flexibility. |

| Surface Finish | Changes how the coil looks and works in different places. |

| Propriétés | Important for jobs that need to fight rust or bend easily. |

FAQ

What is the difference between mill finish and anodized aluminum coils?

Mill finish coils have a plain metallic look and no extra layer. Anodized coils get a protective layer that fights rust and damage. You can ask Yutwin Aluminum Foil for advice on which finish fits your project.

Which aluminum coil grade works best for marine applications?

You should choose grades like 5052 or 5083 for marine applications. These grades resist saltwater and last longer. Yutwin Aluminum Foil offers coils that work well for boats and ships.

How do I select the right thickness for my aluminum coil?

You need to know your project’s needs. Thicker coils give more strength. Thinner coils bend easily. Yutwin Aluminum Foil can help you pick the right thickness for your job.

What is 8011 cold-rolled aluminum coil used for?

You often use 8011 cold-rolled aluminum coil in packaging, bottle caps, and household foil. It bends well and resists corrosion. Yutwin Aluminum Foil supplies this coil for many industries.

Can I paint aluminum coils myself?

You can paint mill finish aluminum coils yourself. Clean the surface first. Use paint made for metal. Painted coils from Yutwin Aluminum Foil come ready for use and last longer outdoors.